3D-printed protective face shields, adaptation of sports masks for respirators, and more... an overview of the initiatives led by units, laboratories and campuses of Université Gustave Eiffel in support of medical staff and hospitals.

Spotlight: Université Gustave Eiffel mobilised for medical staff during the COVID-19 epidemic

ESIEE Paris (Marne-la-Vallée campus)

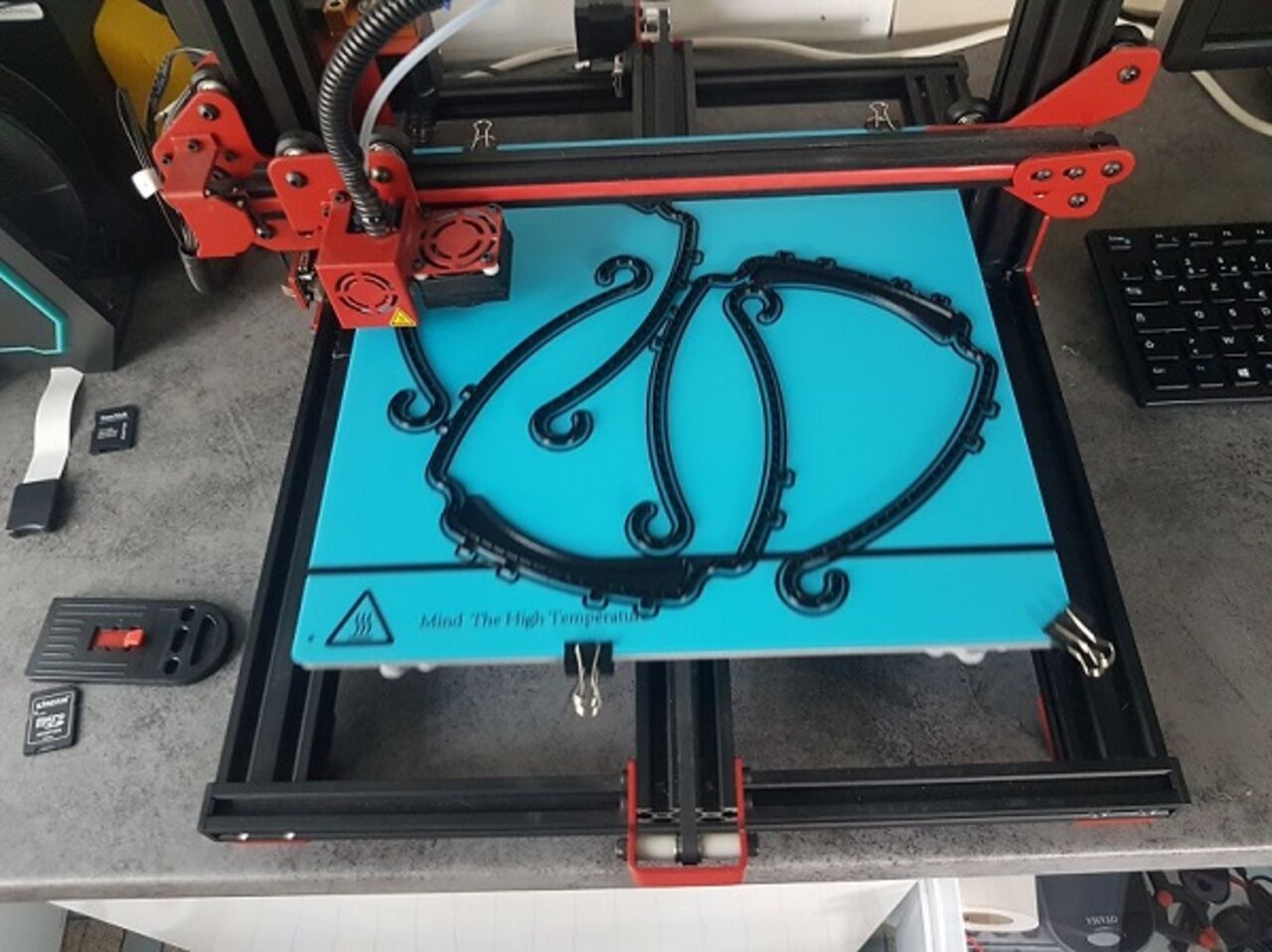

Following a call by the Cochin Institute to offset the shortage of masks, ESIEE Paris responded by producing face shields with the help of a 3D printer, transparency film and elastics. These shields were produced for the medical staff at the Cochin Hospital in Paris. Under the initiative of a member of INSERM’s Ethical Committee, the school also put together a list of open-source procedures to manufacture protective and medical equipment (e.g., syringe pumps) using 3D printing, for distribution to counterparts in the Southern countries.

ESIPE (Marne-la-Vallée campus)

In addition to 3D-printed face shields for medical staff, ESIPE also donated its personal protection equipment (PPE). Various batches were distributed according to the needs of freelance nurses.

MSME (Marne-la-Vallée campus)

Called upon by INSIS (Institute for Engineering and Systems Science) to carry out an inventory of equipment, the MSME laboratory also responded to a request from the Henri Mondor hospital in Créteil. Its bio-mechanics team at UPEC - Paris-Est Créteil University developed a solution to offset the shortage of non-invasive ventilation (NIV) masks. The solution enabled the ventilation of patients via continuous positive airway pressure (CPAP). A 3D printer was made available. Following a week of computer-based design, 3D printing and tests on 15 versions, doctors (emergency physicians, medical physicians and surgeons) validated the ‘Easy Mask’ version which safely transforms Decathlon-brand sports masks into NIV masks with the same safety and effectiveness criteria as CPAP on a standard mask. The production of connecting tubes was carried out in the operating theatre with a specific 3D printer.

LBA (Mediterranean campus)

In Aix-Marseille University (AMU), the production of face shields for medical staff was launched by the Laboratory for Applied Bio-mechanics (LBA), with the support of its industrial partners: Shark, Biotech Dental, Pain de sucre, 3Dmedlabs and Initial. Four 3D-printed face shield production sites were set up in association with the Public Hospitals of Marseille body (AP-HM): The Saint-Jérôme Faculty of Science, the Luminy Faculty of Science, the Timon Medicine Campus (printing and logistics) and the Nord Medicine Campus (the LBA). Within a few hours, LBA became a production and logistics centre for the Nord hospital.

Nantes campus

In West France, solidarity ‘makers’, such as Yannick Falaise from Université Gustave Eiffel, also went into action for the non-profit group Visières de l’Atlantique (‘Atlantic Face Shields’). Thanks to widespread mobilisation and fund-raising to buy consumables for 3D printers, the group was able to provide protective equipment to hospitals and medical centres.

LBMC (Lyon campus)

A medical doctor/PhD student from LBMC (Bio-mechanics and Shock Mechanics Laboratory) took part in a normative action by AFNOR (French Standardization Association) for protective masks. In addition to providing the model for the mask, AFNOR set up a supply and demand link-up platform for protective masks. LBMC delivered the equivalent of 5 carloads of protective equipment for medical workers.